Filter News

Area of Research

- Advanced Manufacturing (1)

- Biology and Environment (3)

- Clean Energy (12)

- Fusion and Fission (8)

- Fusion Energy (7)

- Isotopes (1)

- Materials (6)

- Materials for Computing (1)

- National Security (11)

- Neutron Science (3)

- Nuclear Science and Technology (11)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Sensors and Controls (1)

- Supercomputing (6)

News Topics

- (-) Advanced Reactors (34)

- (-) Security (24)

- 3-D Printing/Advanced Manufacturing (117)

- Artificial Intelligence (88)

- Big Data (50)

- Bioenergy (88)

- Biology (96)

- Biomedical (58)

- Biotechnology (21)

- Buildings (55)

- Chemical Sciences (60)

- Clean Water (29)

- Climate Change (95)

- Composites (25)

- Computer Science (184)

- Coronavirus (46)

- Critical Materials (25)

- Cybersecurity (35)

- Decarbonization (75)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (192)

- Exascale Computing (36)

- Fossil Energy (5)

- Frontier (41)

- Fusion (53)

- Grid (61)

- High-Performance Computing (83)

- Hydropower (11)

- Irradiation (3)

- Isotopes (49)

- ITER (7)

- Machine Learning (46)

- Materials (141)

- Materials Science (137)

- Mathematics (6)

- Mercury (12)

- Microelectronics (2)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (60)

- Net Zero (12)

- Neutron Science (130)

- Nuclear Energy (105)

- Partnerships (41)

- Physics (59)

- Polymers (31)

- Quantum Computing (31)

- Quantum Science (66)

- Renewable Energy (2)

- Simulation (45)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (122)

- Transformational Challenge Reactor (7)

- Transportation (94)

Media Contacts

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

Deborah Frincke, one of the nation’s preeminent computer scientists and cybersecurity experts, serves as associate laboratory director of ORNL’s National Security Science Directorate. Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

Twenty-seven ORNL researchers Zoomed into 11 middle schools across Tennessee during the annual Engineers Week in February. East Tennessee schools throughout Oak Ridge and Roane, Sevier, Blount and Loudon counties participated, with three West Tennessee schools joining in.

David Kropaczek, director of the Consortium for Advanced Simulation of Light Water Reactors, or CASL, at the Department of Energy’s Oak Ridge National Laboratory, has been named a fellow of the American Nuclear Society.

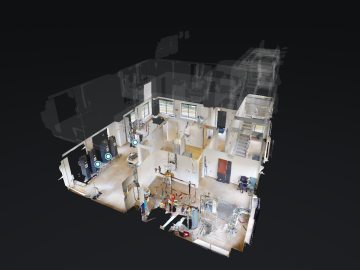

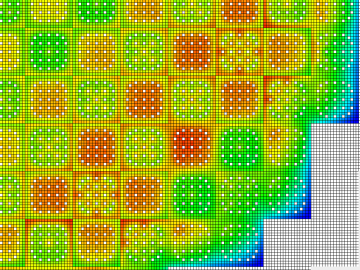

ORNL has added 10 virtual tours to its campus map, each with multiple views to show floor plans, rotating dollhouse views and 360-degree navigation. As a user travels through a map, pop-out informational windows deliver facts, videos, graphics and links to other related content.

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.

Irradiation may slow corrosion of alloys in molten salt, a team of Oak Ridge National Laboratory scientists has found in preliminary tests.

A developing method to gauge the occurrence of a nuclear reactor anomaly has the potential to save millions of dollars.

As CASL ends and transitions to VERA Users Group, ORNL looks at the history of the program and its impact on the nuclear industry.

Horizon31, LLC has exclusively licensed a novel communication system that allows users to reliably operate unmanned vehicles such as drones from anywhere in the world using only an internet connection.